Introduction

The VR Refiner is installed into the fuelling stations vent system to enable all displaced petrol vapours normally lost to site to be processed, converted to fuel and returned to the storage tank for immediate resale.

The installation is fast, low cost, and significantly the VR Refiner starts to contribute a profitable revenue stream from day one.

The new VR Refiner has incorporated all the latest technical design improvements gained from years of successful operational experience in various geographical and environmental conditions around the World.

The system has proven reliability and is now even more efficient whilst running costs are lowered. The latest model is smaller and lighter, quality materials ensure a minimum operating life of 20 years.

The System

During normal site operation and tanker deliveries displaced Petrol vapour moves from the Underground Storage Tank 3 through the manifolded vents 4 , 5 into the VR processing chamber 1.

The multi phase processing chamber is kept at very lower temperature by the VR control module 2 which incorporates advanced refrigeration and sophisticated electronics. The vapour is condensed in the chamber back to fuel where it is stored at the base of the chamber.

The vapour with fuel removed continues through the outlet pipe 6 towards the breather vent 8 and stage one Tanker connection 7 if fitted.

Process fuel is stored, measured and then returned to the UST for immediate resale via the fuel return line 9.

Proving the business case

By using the latest monitoring system all direct processed fuel can be measured and accounted for via the on line FMT telemetry system accessed via Fuel Management Technologies web site portal.

Third party testing has proven the efficiency and retailers can immediately see the money they are making from the first day of installation.

Third party testing has proven the efficiency and retailers can immediately see the money they are making from the first day of installation.

Features and Benefits

An Eco Investment that creates a profitable revenue stream A passive system easy and low cost to install and maintain.

- Retains the Retailers vapours to process to re-saleable fuel.

- Third party tested for performance and reliability.

- Improves the environment, lowers carbon footprint.

- Low power consumption using latest technology.

- Minimal maintenance with no site disruption.

- Positive commercial business case.

- Virtually eliminates harmful on-site gasoline emissions.

- Works with all site configurations.

- Road tankers return to depot with Lower Explosive Limit.

- Accurate wet stock monitoring and reporting.

- Does not interfere in any way with normal site operations.

Technology and Innovation

Fuel Management Technologies embrace innovation, it’s integral to our success. Research and development has included co-operation with International universities, working alongside major mechanical and electronics suppliers, coupled with years of on-site successful operational experience.

The Multi phase Cryo-Coalescent technology permits the condensation of the petrol vapours in a passive way without affecting the normal pressure and atmospheric conditions in all the storage tanks and pipes.

We use a condensing technology of hydrocarbon vapour's that does not in any way alter the chemical or material composition of the recovered fuel.

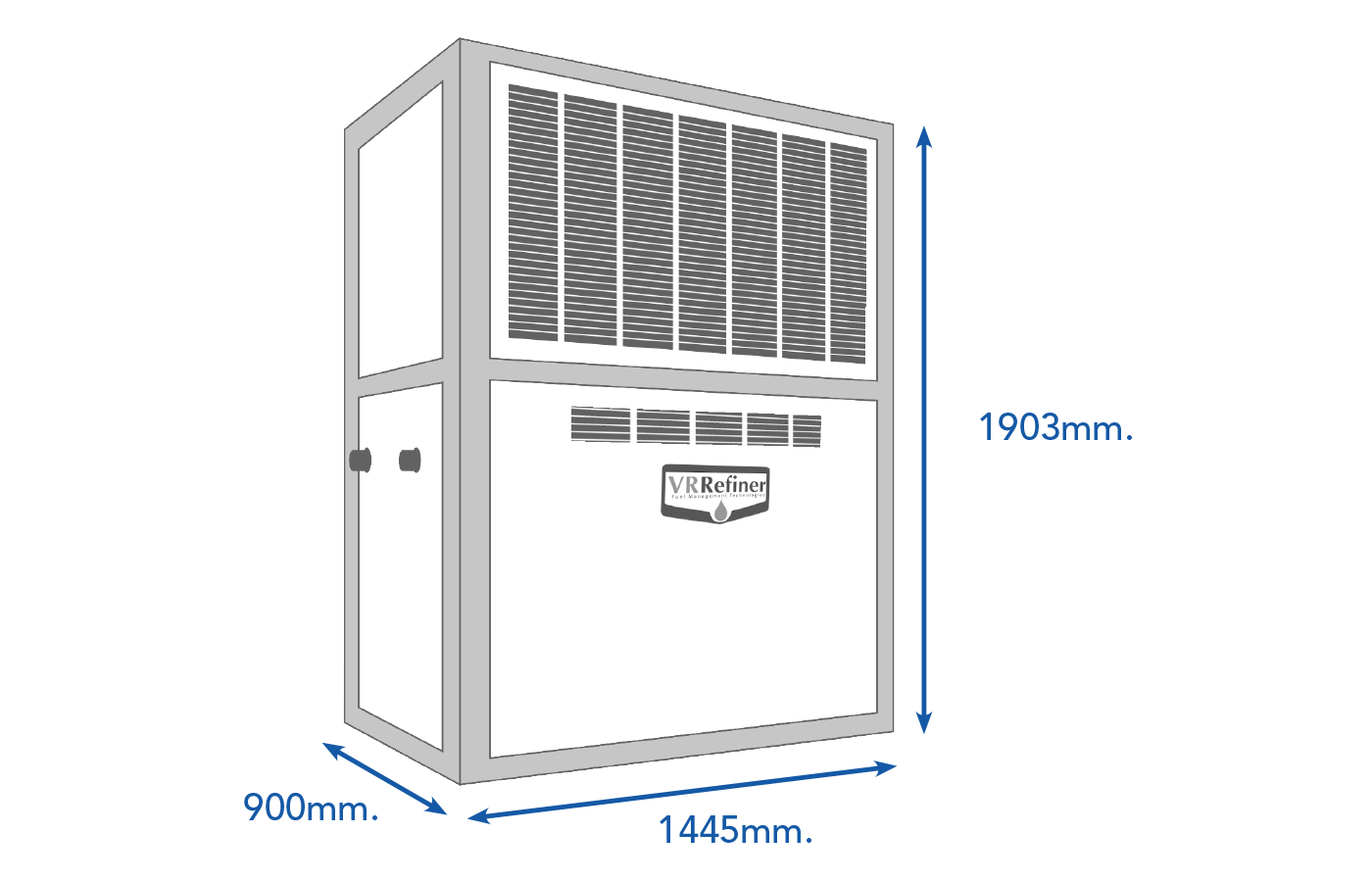

Innovative refrigeration design with capacity control combined with temperature sensing cycling provides therequired process temperatures combined with low power consumption. Latest compact design, a unique architecture and integrating the system on a single base provides a fast installation and commissioning period. Advanced ‘state of the art’ digital and mechanical controls developed with World leading companies.

The Multi phase Cryo-Coalescent technology permits the condensation of the petrol vapours in a passive way without affecting the normal pressure and atmospheric conditions in all the storage tanks and pipes.

We use a condensing technology of hydrocarbon vapour's that does not in any way alter the chemical or material composition of the recovered fuel.

Innovative refrigeration design with capacity control combined with temperature sensing cycling provides therequired process temperatures combined with low power consumption. Latest compact design, a unique architecture and integrating the system on a single base provides a fast installation and commissioning period. Advanced ‘state of the art’ digital and mechanical controls developed with World leading companies.

Service and Support

Fuel Management Technologies shall provide all the necessary support and training to ensure that full product performance and the expectations of our customers are met. Working alongside our trained local support engineers we can complete a detailed survey of each site and establish the optimum installation, additionally ensuring local maintenance and support is available.

How it works?